|

|

|

|

#1 |

|

Registered Member

Join Date: Nov 2000

Location: Surrey, BC

Posts: 454

|

5 Feet, 110 Gallons of Fun

Hello everyone, I figured it would be good to start my own build thread for several reasons. I got a lot of ideas and help from various folks on RC, so I would like to pay it back even a bit if I can. Also, it would be neat to see progress for myself and how things evolve and change.

I picked up acrylic (5 foot x 18" x 24") 110 gallon tank several months ago. This is what it looked like when I got it    As you can see it was in a somewhat rough shape, but all seams were looking good and it held water fine. After week long water test I cleaned up algae with Mr Clean eraser. This stuff is magic. I could now see what I was actually working with. I am guessing PO tried to buff out scratches, used higher grit sand paper and then gave up.    Lots of scratches everywhere.

|

|

|

|

|

|

#2 |

|

Registered Member

Join Date: Nov 2000

Location: Surrey, BC

Posts: 454

|

I knew I would have to sand the whole tank down and then buff/polish. Kicker was, I never did anything of this sort before, so I spend several weeks of research, asking question on clay-boa and varoius other forums. It was actually slief thread on RC and videos on polishing scratches out of acrylic aquarium that I found on RC that got me thinking about this to begin with. If you havent seen these videos, and plan on doing polishing, you should read this thread and watch videos for sure

http://reefcentral.com/forums/showthread.php?t=2538092 Since scratches were all over, I decided to sand down whole tank inside and out. I started with 400 grit sandpaper and used palm sander for the whole job. This thing was damn loud! I had to use ear plugs or else I wouldnt be able to hear anything for weeks. Sanding outside was nice and easy and quick, however inside was a lot harder due to the brace on the top. It was hard to get in and properly sand it down, as I couldnt get good grip on the sander. It wanted to fly all over the place, so that wasnt fun. Here is what tank looked like after 400 grit    Needless to say I was freaked out at this point, and thought to myself more than once what the hell have I done. I went 400, 600, skipped to 1000 because I got different sand paper and their 800 felt rougher than 600 I used, 1200, 1500 and finally 2000. This took several weeks, as I was doing this after work. Since sander was really loud, I didnt want neighbors to complain, so I only did few hours every day or 2. This is what it looked like after 2000 grit  I could at least somewhat see inside it, so I was happy to see it was clearing up as grit progressed. Next up was polishing and buffing... |

|

|

|

|

|

#3 |

|

Registered Member

Join Date: Nov 2000

Location: Surrey, BC

Posts: 454

|

Another thing I never did was buff/polish. Not just acrylic, but anything at all. Again I spent about a week reading up various forums, watched videos and so on. I decided I will use Novus 3, 2 and 1 for this final step. I ended up getting a really good deal on dual action polisher, and bought Chemical Guys cutting, polishing and finishing pads.

I started off with Novus 3 and used Medium/Heavy cutting pad. I had DA at speed 2 out of 6. This is what tank looked like once it was done    I was really shocked to see this much of a difference, and definitely didnt expect it. I could still see light scratches from sander, but felt good about it, knowing I still have Novus 2 to use. I used Novus 2 with same pad as with Novus 3 (new pad, but same type). After Novus 2, all the scratches were gone, and tank was looking really good. Again I wasnt expecting this   Finally, I used Novus 1 twice. 1st time it was with Light/Medium polishing pad and then with finishing pad. I felt that after 1st run, there was still some novus 2 left behind, so I wanted to use softer pad. After Novus 1, it looked great to me at least (all dirt is splatter from sanding and polishing on the black stand behind the tank)     There is a bit of hazing when I look through some panels, but I will take it. Once it is filled with water, it wont be visible at all, and considering what it looked like when I started this journey, I am extremely happy with how it turned out. Next up, building a stand. |

|

|

|

|

|

#4 |

|

Registered Member

Join Date: Nov 2000

Location: Surrey, BC

Posts: 454

|

I decided to use RocketEngineer's tried and true template for my stand build. There is a massive thread on RC with info on it, so I would suggest to anyone looking for stand ideas to spend some time and read through it

http://reefcentral.com/forums/showthread.php?t=1169964 Since it was a 5 foot tank, I decided to go with 2x6s for the top frame. Height of the stand is 37.5". That should give me plenty of room underneath to fit skimmer and all other goodies that will be needed, as well as do maintenance when needed. At 1st my plan was to use 40G breeder for sump, however I got IceCap 36XL sump. Issue now was that tank width is 18" but sump is 24". I had to modify my plans, and came up with this in the end     I extended top and bottom frame to 24" so that sump can fit at the bottom, and added 2 off centered vertical supports. These are mostly for doors or however I decide to skin, and to be able to separate equipment from the sump. I still havent decided how that will all work out, so that is TBD for sure. I will leave back completely opened for air circulation, and will leave opening between 18-24 inches at the top open as well. It will give me lots of room for plumbing and other things that need to move between DT and sump. Sides will be skinned, so only opening that will be visible will be that one at the top. I caulked all the joints inside and outside with Alex Plus Acrylic Latex and primed it with 2 coats of Kilz Original. Plan is to start skinning it this weekend. Will post up as it progresses. |

|

|

|

|

|

#5 |

|

Registered Member

Join Date: Jun 2008

Location: South Dakota

Posts: 368

|

Always crazy watching threads like this develop, since so many completely different talents are shown. Tank and stand are looking great so far, that's for sure. Definitely bigger cojones than me to do a complete sand and polish on an acrylic tank, but looking at your results I can see it IS possible to do.

Can't wait to see what's next. -Hans

__________________

This hobby would be easier if my local stores had more fish. https://www.reefcentral.com/forums/showthread.php?t=2701233 Current Tank Info: Slowly stocking up 150 gallons, only a little livestock right now. |

|

|

|

|

|

#6 |

|

Registered Seaweedist

Join Date: Feb 2004

Location: Boulder, CO

Posts: 5,807

|

Great job getting that acrylic tank clear again! It's a LOT of hard work.

I have a Clarity Plus acrylic 180 tall tank. One thing I didn't like is the top openings were too small, making working in the tank too difficult. So I jigsawed much bigger openings, using a hole saw to cut round corners. That's one of the great things about acrylic tanks - so easy to mod yourself! Good luck with the rest of the build! I look forward to seeing what you come up with.

__________________

As many naturalists and environmentalists have suggested, we should set aside our arrogance, our desire to conquer and control everything, and walk hand in hand with Mother Nature. -Walter Adey Current Tank Info: 180g Seagrass Sandbar Lagoon, START DATE November 28, 2018 |

|

|

|

|

|

#7 |

|

Registered Member

Join Date: Nov 2000

Location: Surrey, BC

Posts: 454

|

Thanks gents! It was quite a bit of work. i think it took me about 20-25 hours total worth of work to get it from starting point to the finished one. Still need to wash it out with bleach/water mixture to get it 100% done, but that should take few min.

I will have to see how things go in regards to the top brace. It was ok so far, but will see how things go once tank is up and running, and if they become too much of an issue. Since acrylic used is thin, I am worried that if I cut part of the brace off, I may run into bigger issues. There is some bowing in the middle of the tanks, both front and back due to thin acrylic, so not sure if I want mess around with that. I think i would rather have a bit of an issue with brace, but not have a flood haha. |

|

|

|

|

|

#8 |

|

Registered Member

Join Date: Nov 2000

Location: Surrey, BC

Posts: 454

|

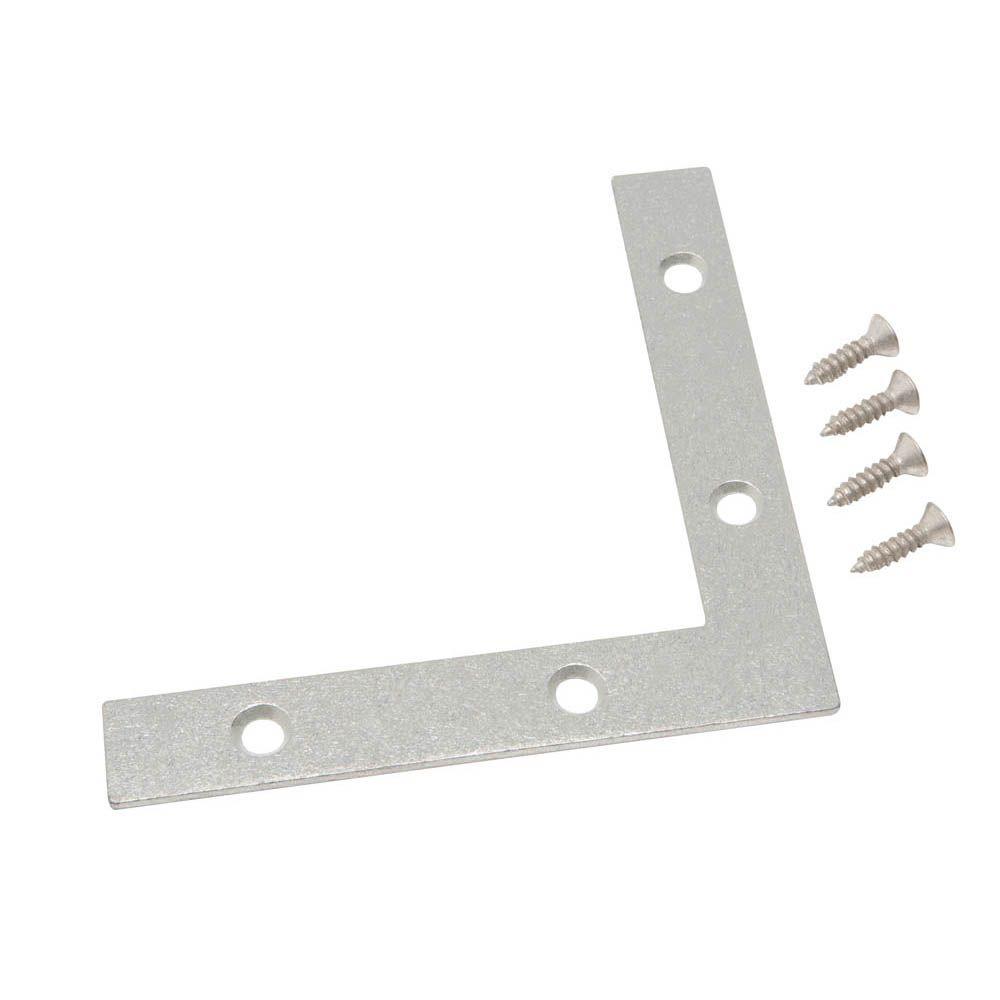

I started working on light mount for the Noopsyche K7 Pro IIs that I will be using. I bought aluminum square tubing for this build. I cut tubing at 45 degree angles and used flat corner braces to connect it all together.

Unfortunately few cuts werent perfect, so there is a gap between the 2 pieces when I connected them. I wanted to make sure that my angles were a perfect 90 degrees.   Not a huge deal as I will use aluminum rods and braze it to fill in the gaps. Once it is primed and painted it shouldnt be visible. I also put 5 pieces of flat aluminum across. This will be used as light mounts.  Finished mount, for now   I actually plan on making this whole thing have adjustable height. I have a plan in my head, so we'll see if it works out. Should be pretty simple to do, so will update once I have more in next few days. |

|

|

|

|

|

#9 |

|

Registered Member

Join Date: Apr 2015

Posts: 55

|

Great cleanup on the tank

|

|

|

|

|

|

#10 |

|

Registered Member

Join Date: Nov 2000

Location: Surrey, BC

Posts: 454

|

Finally have an update. Weather has been crappy and cold last few months, and since I do most of the work in the garage, it was cold. That prevented me from doing much. I finished light mount, or at least have it 99% done.

As can be seen above, I made a frame using square aluminum tubing and didnt lineup some of the corners perfectly. I used Blue Demon Triple Play Low Temp Aluminum-Zinc Brazing Rod and MAP gas to fill in the gaps that can be seen above, and to braze legs to the whole structure. Since I never did this before, there was a lot of reading and watching of youtube videos. Really important thing that absolutely has to be done to get this to creat proper hold is to make sure that aluminum tube is up to the temp. If it is not, and you melt the rod onto it, it will not stick at all, and will create for really weak connection. Few pieces I had to break off several times as I couldnt get one side to braze properly. Once I figured out how much I need to heat up the tube, it was really easy and fast work from there. Once it was all done, I painted it black, mostly to cover imperfections in brazing as much as possible        As you can see, there are legs inside of legs. Unpainted legs are brazed to the frame, and then I created another set of legs and base that top frame goes into (all black part). This will allow me to move whole top frame up and down about 5 inches. I wanted to have option of moving it, so that when I start figuring out PAR and height I should place lights at, I can play around with height and see which one works the best. I just have to drill few holes to hold it at various heights. Finally, I plugged square tube ends at the bottom with plastic caps. Also, light mounts (aluminum bars) where NP lights are mounted can be removed via screws, so if I decide to use different lights I would just have to space those bars around in new position. Then again i can play with height and re-adjust as necessary. I also made sure that I have enough space so that I can mount a single T5 fixture on each side, if/ when time comes for that |

|

|

|

|

|

#11 |

|

Registered Member

Join Date: Aug 2011

Location: Tucson AZ

Posts: 121

|

Great build. I am following along.

|

|

|

|

|

|

#12 |

|

Registered Member

Join Date: Jun 2008

Location: South Dakota

Posts: 368

|

Great, now I want to build myself a light rack similar to yours. Maybe later, gotta get the tank on a stand first.

-Hans

__________________

This hobby would be easier if my local stores had more fish. https://www.reefcentral.com/forums/showthread.php?t=2701233 Current Tank Info: Slowly stocking up 150 gallons, only a little livestock right now. |

|

|

|

|

|

#13 | |

|

Registered Member

Join Date: Nov 2000

Location: Surrey, BC

Posts: 454

|

Quote:

|

|

|

|

|

|

|

|