|

|

|

|

#1 |

|

Registered Member

Join Date: Mar 2008

Posts: 1,158

|

Holes in return pipe from sump?

Heard you should drill a hole in the return line from the sump? Is this true if so how big and for what reason?

|

|

|

|

|

|

#2 |

|

Registered Member

Join Date: Jun 2008

Location: Dayton, Ohio

Posts: 73

|

You'd put the hole at the top of your return pipe just below water level. It is for a siphon break. In the event of a power outage or pump failure, your return line could create a siphon pulling all your tank water down to the sump, resulting in a flood. With the hole, once the water level falls below said hole, air enters and breaks the siphon. The hole shouldn't be very big at all. Just enough so air enters. You'll need to check it regularly to make sure it isn't clogged with anything though. Alternatively you could install a check valve in your return line which lets water go up but not back down.

|

|

|

|

|

|

#3 |

|

Registered Member

Join Date: Apr 2006

Location: Milwaukee, WI

Posts: 306

|

When the pump is off, it prevents siphoning down to the bottem of your return. The siphon breaks at the point where the hole is. Drill at top of return. 3/8's should work.

__________________

Zach Current Tank Info: 37g reef, 25g sump, OR 2500, Octo-150, Calfo overflow, 150w HQI Pheonix 14k, T5 retro, w/ closed loop, Little Giant 3-MDQX-SC, UV, PhosReactor, CarbonReactor, 1/10 Prime chiller |

|

|

|

|

|

#4 |

|

Moved On

Join Date: Jun 2007

Location: Laguna Niguel, CA

Posts: 7,497

|

The idea is to help out with back-flow if the power goes out. A better way in my opinion is to adjust the output nozzles of your return lines so that they are relatively close to the surface of the display tank. Once the water drains to the nozzle opening it would let air in and create a siphon-break. At that point the water should stop back-flowing from the display to the sump.

|

|

|

|

|

|

#5 |

|

Registered Member

Join Date: Mar 2006

Location: Homeless

Posts: 197

|

Ok, couple things here. If you have a check valve this really isn't nessicary. It is used in lieu of a check valve to attempt to stop the water from siphoning from your tank to the sump through the return line.

The hole would be drilled just below the water level of your return line in the tank. This way if your tank looses power it will begin to siphon and then the line would suck air and the siphon will break. You leave most of the water in the tank and don't have your sump overflowing from the excess water. |

|

|

|

|

|

#6 |

|

Registered Member

Join Date: Mar 2008

Posts: 1,158

|

water doesnt flow out of it?

__________________

IM10G Nano - MP10, AI Nano, RKL |

|

|

|

|

|

#7 |

|

On Yer left!

Join Date: Sep 2004

Location: Northern VA

Posts: 18,777

|

The best method to prevent back siphoning is to not have your return lines too deep into the display to begin with. Position them just below the surface and you have a reliable system that wont fail.

__________________

- Scott |

|

|

|

|

|

#8 |

|

Registered Member

Join Date: Mar 2008

Posts: 1,158

|

Yeah if i have my overflow in my tank thats connected to my bulkhead at the top of the tank, would it stop pushing water to the sump after it sunk below the overflow?

__________________

IM10G Nano - MP10, AI Nano, RKL |

|

|

|

|

|

#9 |

|

On Yer left!

Join Date: Sep 2004

Location: Northern VA

Posts: 18,777

|

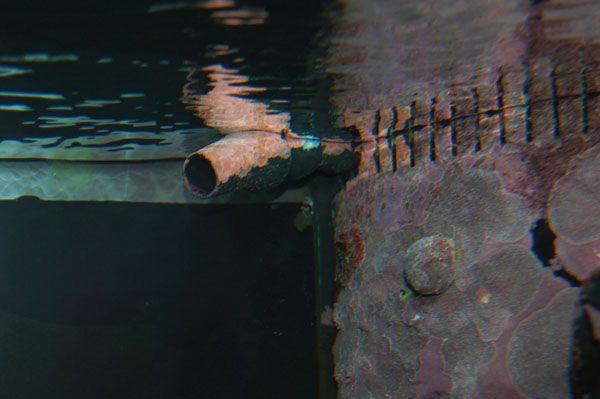

It will drain to the lowest point. The level will drop to the bottom of the overflow teeth and also to the level of the return opening. In the pic below, it wont drain much below the overflow.

__________________

- Scott |

|

|

|

|

|

#10 |

|

Premium Member

Join Date: Jun 2007

Location: Cheektowaga

Posts: 851

|

Check valves are known to fail.

|

|

|

|

|

|

#11 | |

|

Reef and Coral Fanatic

Join Date: Jul 2008

Location: Lexington, Ky.

Posts: 1,739

|

Quote:

__________________

Chris Kirkland Reef Nerd. Current Tank Info: Getting back into the hobby. |

|

|

|

|

|

|

#12 |

|

Registered Member

Join Date: Nov 2006

Location: Chicago area / DuPage Co

Posts: 1,596

|

Not only do check valves fail at some point some also have metal internal parts.

__________________

Never wrestle with a pig, you'll just get muddy and besides the pig likes it !!! Recently retired aberrant antisocial behavior modificationist. Current Tank Info: Help the helpless, not the clueless. And yes that is a political opinion. |

|

|

|

|

|

#13 |

|

Registered Member

Join Date: Jul 2006

Location: Far Away...

Posts: 108

|

Drilling would be the most simple and easy method to prevent back siphon... as well as placing your returns as high as possible...

|

|

|

|

|

|

#14 |

|

Moved On

Join Date: Jan 2002

Location: NW Phoenix

Posts: 16,621

|

The ONLY foolproof method is keeping the returns close to the surface and providing ample room in the sump to contain that very easily calculated small amount of water that will backsiphon until the return is exposed and you have a positive air gap. Drilled holes and check valves are not necessary and are not wanted as both require maintanance. Even with cleaning and maintenace theer is no guarantee the power does not go off 10 minutes later and a snail parks ove rthe driled hole or gets stuck in the flapper of the valve.

If you are just doing it now, do it right the first time and you can sleep peacefully at night. |

|

|

|

|

|

|