|

|

|

|

#1 |

|

Registered Member

Join Date: Sep 2000

Location: Gaithersburg, MD (D.C. Metro Area)

Posts: 1,970

|

Can Uniseals Sustain Pipe Pull-out Pressure Against Them?

I am considering using a uniseal to connect outlet of external pump to my saltwater mixing bin, with water blasting diametrically straight into bin through the side. With a 1900 gph pump (yes, a lot of flow!), I'm wondering whether uniseal is strong enough to hold the pipe from pump outlet in position, or whether thrust of the water would push back against uniseal so forcefully that the uniseal would allow the pipe to slip outwardly over time (in which case bulkhead would be better choice).

Thanks.

__________________

Resident Patent Attorney Last edited by Kengar; 06/12/2018 at 09:01 AM. Reason: clarify the question |

|

|

|

|

|

#2 |

|

Registered Member

Join Date: Sep 2003

Location: North Carolina

Posts: 20,050

|

I personally would likely have no problem using a uniseal for that application and do not think it will be a problem at all.. I would certainly try it for sure...

There are variables at play here.. In general a uniseals axial pullout rating is dictated by wall thickness of the wall in which the uniseal is being installed in and the strength of that material too.. That will effect the amount of friction/force being applied to hold that pipe in place.. If you are using a 50g drum or similar they usually have sufficient wall thickness and are stiff enough to where I wouldn't worry about it at all.. But a garbage can "may" be a different story.. In either case I really doubt pullout is going to be a problem.. But just throwing that out there..

__________________

Who me? |

|

|

|

|

|

#3 |

|

Registered Member

Join Date: Sep 2000

Location: Gaithersburg, MD (D.C. Metro Area)

Posts: 1,970

|

Actually, I may have mooted the issue by a design mod. Run pipe to center of the drum and put on an elbow facing downward (long sweep), to cause flow to impinge and run radially outwardly along bottom (like a starburst) and churn the salt. Yes, that would put bending moment onto the uniseal, but pump sitting outside bin would support opposite end of pipe and balance it out. (This is why I get no work done........ mind wanders!)

__________________

Resident Patent Attorney |

|

|

|

|

|

#4 |

|

Registered Member

Join Date: Sep 2003

Location: North Carolina

Posts: 20,050

|

Sounds just like typical "problem solving" to me..

Always best when done "prior" to having the problem vs after IMO...

__________________

Who me? |

|

|

|

|

|

#5 | |

|

Registered Member

Join Date: Jan 2012

Location: Idaho

Posts: 92

|

Quote:

Edit: I glued all the vertical joints on my tree and friction fit all the horizontal pipes so it can all be removed. I glued the vertical joints to insure nothing fell off due to gravity. I figured the horizontal pipes weren't a concern in that department. HTH |

|

|

|

|

|

|

#6 |

|

Registered Member

Join Date: Sep 2000

Location: Gaithersburg, MD (D.C. Metro Area)

Posts: 1,970

|

at risk of turning this into a thread for DIY. . . . .

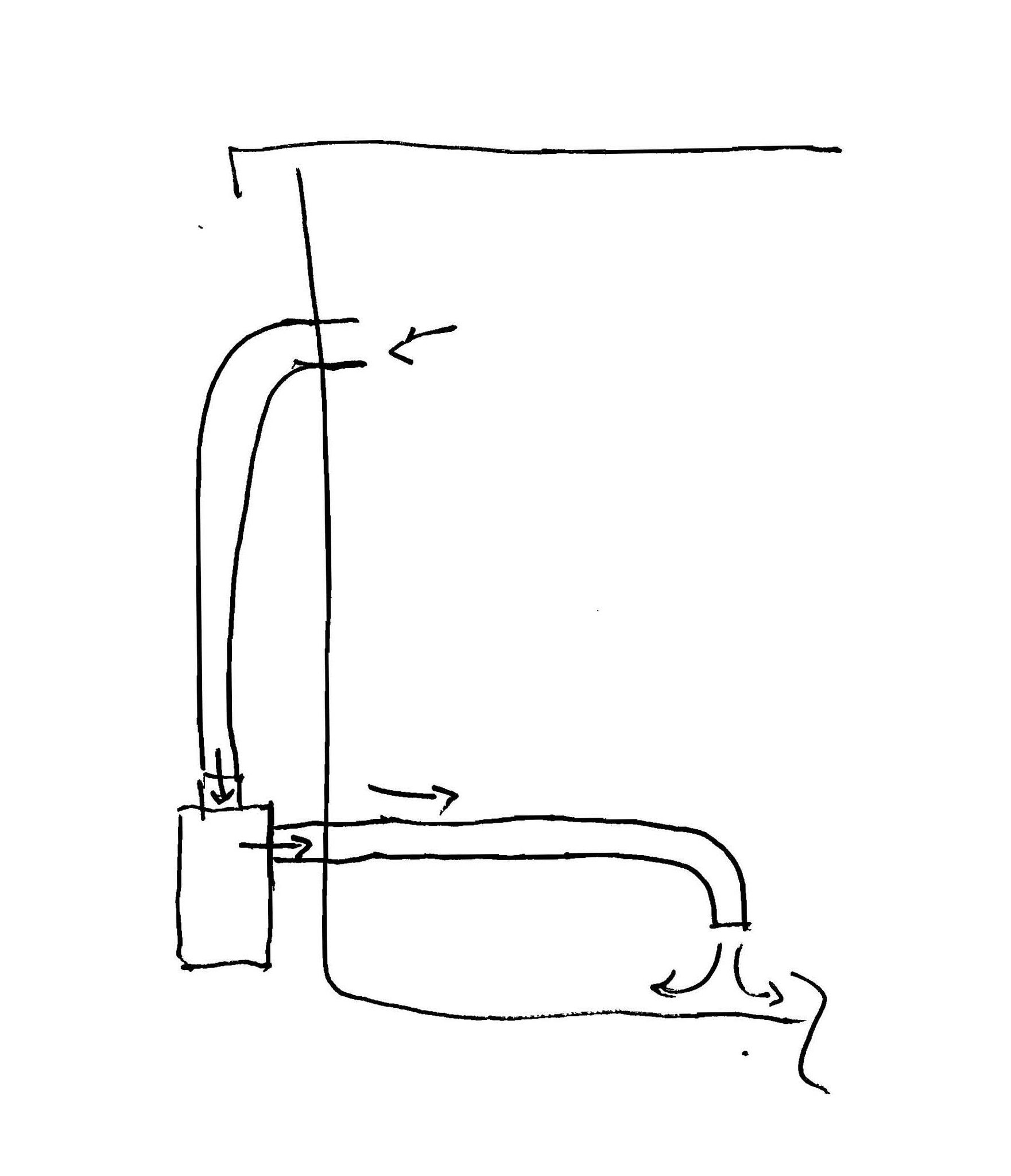

I think using a bulkhead will be better. this way, I can assembly the internal pipe and fasten it to the bulkhead, then reach down into bin and insert shank of bulkhead through the wall to extend outwardly. Otherwise, trying to glue up parts down inside bin would be a pain. FYI, here is the configuration I have in mind: [IMG][url=https://flic.kr/p/26MobQe]

__________________

Resident Patent Attorney |

|

|

|

|

|

#7 |

|

Registered Member

Join Date: Jan 2012

Location: Idaho

Posts: 92

|

I did all my gluing outside of the tank. No big deal really. The only reason I glued anything was to insure nothing came apart due to gravity and the weight of my "tree" hanging. Like I said its only the vertical joints that are glued on my setup.

|

|

|

|

|

|

#8 |

|

Registered Member

Join Date: Oct 2016

Location: Largo, Florida

Posts: 361

|

Um, IDK but your sketch seems backwards,Possibly problematic, Most setups feed the pump from the bottom, Then up and over the top to recirculate mix water and salt. As your water level drops pump would lose siphon and run dry, Not good. I use a swirly vortex,Or you could just blast straight down. It will circulate as little as 3.5" of water in the mixing barrel. Oh, and I use Uniseals.

0410171038 - Edited (1).jpg 0114171839 - Edited.jpg Last edited by Smokey Stover; 06/13/2018 at 06:34 AM. Reason: add on |

|

|

|

|

|

#9 | |

|

Registered Member

Join Date: Sep 2000

Location: Gaithersburg, MD (D.C. Metro Area)

Posts: 1,970

|

Quote:

That's just to mix saltwater. Bin will be full. More compact arrangement, and minimizes backpressure on output by having output go straight into the bin (with just a single long sweep elbow to point it down).

__________________

Resident Patent Attorney |

|

|

|

|

|

|

#10 |

|

Registered Member

Join Date: Oct 2016

Location: Largo, Florida

Posts: 361

|

OK, Now I'm just wondering how your going to get the water out and into your tank? Siphon into buckets? (yea I overthink things too lol)

|

|

|

|

|

|

#11 | |

|

Registered Member

Join Date: Sep 2000

Location: Gaithersburg, MD (D.C. Metro Area)

Posts: 1,970

|

Quote:

Originally, I had set up for a single pump to be located between the two bins for recirculating brewing, too, with a circuit I had built with reversing flow pathways and a pair of diverter valves to control what went which way (i.e., water from bin either being fed to supply pump to Renew or to the recirculating pump). See the diagram here: http://www.reefcentral.com/forums/sh....php?t=2674394 What I found, though, was that with all the elbows and turns, even with a 1900 gph pump, I wasn't getting very forceful flow out of the pipes extending down in to the bins to mix salt. So I'm scrapping the whole circuit concept and will just put a pump on each of the two bins. Hence this line of thinking....

__________________

Resident Patent Attorney |

|

|

|

|

|

|

|