|

|

|

|

#451 | |

|

Registered Member

Join Date: Jul 2009

Location: Spokane, WA

Posts: 316

|

Quote:

|

|

|

|

|

|

|

#452 |

|

Registered Member

Join Date: Jul 2009

Location: Spokane, WA

Posts: 316

|

Just to reiterate what Andy said about installing ceramic washers:

PLEASE us pliers when reinstalling the impeller into the pump housing. The housing's magnetic pull is strong enough to "suck" the impeller in with such force that it'll break the ceramic washers from the impact. |

|

|

|

|

|

#453 | |

|

Registered Member

Join Date: Feb 2004

Location: Wallingford, CT

Posts: 4,990

|

Quote:

|

|

|

|

|

|

|

#454 |

|

Registered Member

Join Date: Jan 2002

Location: Mississippi

Posts: 1,206

|

agreed, i always thought it would be nice to have a larger input option to allow easier drain setup

|

|

|

|

|

|

#455 |

|

Registered Member

Join Date: Jul 2009

Location: Spokane, WA

Posts: 316

|

How's everyones ceramic washers doing?

|

|

|

|

|

|

#456 |

|

Registered Member

Join Date: Feb 2004

Location: Wallingford, CT

Posts: 4,990

|

Not yet Jim, waiting for my maintenance schedule. Did you install yours and how did it go, no hitches or hiccups?

|

|

|

|

|

|

#457 |

|

Registered Member

Join Date: Mar 2003

Posts: 1,133

|

If i were you guys I'd do it sooner rather then later. Those SS washers are eating away at your Impeller everyday. And last I checked its nearly impossible to get it from Fins Reef.

I can inspect my pumps anytime simply by doing the following. 1. shut off pump 2. put 2 7/8" cork ( Might be smaller then 1". I think maybe 5/8?? ) on the inside of the skimmer to plug the holes where the pumps are. I have an external model so thats what I do. 3. Use the air tube to drain the water inside the pump. 4. put towel under pump. 5. remove pump. A small amount of water will come out. 6. disassemble pump and replace washers. 7. put things back , remove cork , put air tube back, turn on pump. |

|

|

|

|

|

#458 |

|

Registered Member

Join Date: Jul 2009

Location: Spokane, WA

Posts: 316

|

Cool idea Andy, never thought of doing it that way...I just stick a powerhead in the skimmer bode and pump all the water into my sump.

I checked the washers at the six week mark and everything seemed fine except there was a tiny bit of wear (almost undetectable) on the shaft where the washers contact it...if this trend continues I'll replace the shaft way down the road, but $20 for a shaft assembly beats $150 for the impeller assembly any day. |

|

|

|

|

|

#459 |

|

Registered Member

Join Date: Apr 2010

Location: Des Moines, IA

Posts: 231

|

I just got my first H&S skimmer. It's an A150 running on a 125g mixed reef. I've actually been having some difficulty getting it dialed in... which has surprised me since people seem to have few issues getting their H&S skimmer up and running.

I bought the skimmer used and the feed pump I was provided doesn't work. So I'm using a small pump I had laying around, however it is about 325 GPH and I see on aquariumspecialty.com that the recommended flow is 150-200. I've been trying to get the bubble level dialed in and it seems that as I turn the turnpipe that the level won't change. It stays low at the base of the neck and as I turn it slightly further it will all of a sudden overflow into the cup. So for some reason there's no in-between setting for me. I'm wondering if it possibly has something to do with the fact that I'm using too powerful of a feed pump. I've also experienced oscillating levels in the skimmer at certain settings which I'm believe is because it's draining too fast out of the pipe and creates a siphon, the siphon causes the skimmer to drain faster (dropping the level in the neck) until the siphon breaks, and then the cycle repeats. This is what originally made me think that the feed pump is a bit too strong. Any thoughts/suggestions? Thanks! |

|

|

|

|

|

#460 |

|

Registered Member

Join Date: Jan 2007

Location: menifee So cal

Posts: 11,042

|

Sounds like your exhaust is causing the skimmer to oscillate trying lifting the pipe from under the water, I drilled holes in mine so the pipe is under water put there are holes above the water to break siphon. The skimmer might need to break in. Can you post pictures?

|

|

|

|

|

|

#461 |

|

Registered Member

Join Date: Aug 2005

Location: Chicago

Posts: 291

|

I found it is best to let the skimmer drain above the waterline.

|

|

|

|

|

|

#462 |

|

Registered Member

Join Date: Dec 1999

Location: Amish Country, PA. USA

Posts: 978

|

The A150 drain pipe should never be below the water line. Half way up the drain outlet pipe is the maximum water level. Why use a pump to feed it? Plumb the feed from the overflow.

Joe

__________________

I put the laughter in slaughter. Current Tank Info: 120 Gallon Oceanic Tech Tank, Two MP40W Gen 2 Vortechs, H & S A-150-F2001 External Skimmer, Oceanic Model 3 Sump, Current Outer Orbit Pro 250 Watt MH/T5 Combo |

|

|

|

|

|

#463 |

|

Registered Member

Join Date: Jan 2003

Location: Costa Mesa, CA

Posts: 366

|

Need help please!

I have A200 with two Eheim pumps and this is my first time setting this skimmer up. I am planning to do gravity feed from drain direct to skimmer but the input fitting is too small 3/4". Do I need to replace this fitting or can someone show me how to plumb this? I assume that I'll definitely need a ball valve to reduce the flow into the skimmer. My drain bulkhead size is 2.5". Thanks for your help. Mike |

|

|

|

|

|

#464 |

|

Registered Member

Join Date: Mar 2003

Posts: 1,133

|

I have an A250 and is very similiar to your A200 (just wider body). I have my skimmer plummed to the over flow. Just use a T fitting where the T fitting have a 3/4" threaded output. On my pluming I am using 1 1/4" for the drain.

So basically Tank -> 1 1/4" T to 1 1/4" -> 1 1/4" ball valve -> 1 1/4" output pipe that goes into the sump under water about 12". The T will also have a 3/4" thread on it where I thread a 3/4" barb. I then run a hose from here directly to the skimmer with no ball valve. You can adjust the flow to the skimmer via the output (1 1/4") ball valve. By the way on the H&S there is no siphon on the pipe due to the design. There is a vent pipe that adjust flow. Now way your gonna get a siphon unless you have some weird plumbing. Last edited by andyman; 03/01/2011 at 12:49 PM. Reason: edit |

|

|

|

|

|

#465 |

|

Registered Member

Join Date: Apr 2006

Location: Aurora, IL

Posts: 2,216

|

Hi, two questions:

1) Can somebody catch me up to speed on what gasket / washer you are replacing? I wasn't able to make sense of the thread... 2) I own an H&S 150 and it has began to leek at the union where the PVC meets the pump. The screw cover that locks the two pieces together only allows you to hand tighten the cover about a 1/8th of a turn, and is designed to not allow to tightened past a certain point. There is water slowly dripping out of the area. Just to clarifiy I am not talking about the two screw on pvc caps that hold the pump to the skimmmer, but where the part that holds the impeler/shaft in place. Is there some gasket that has gone bad or has anyone else experienced this problem? I have inspected the gaset and it is very clean, not brittle, it looks to be in very good condition The only thing I can think of is the gasket has become thinner? thus letting water to drip out?? Thanks! |

|

|

|

|

|

#466 |

|

Registered Member

Join Date: Mar 2003

Posts: 1,133

|

You can use some silicon grease on the o-ring in an attempt to swell the o-ring to make a tighter fit. Or you can buy another o-ring at the local home depot (either same size or anything bigger) as long as the cross section of the oring is about the same or bigger. If the oring is much larger in diameter take a razor cut it to proper size and use super glue to put it back together. This technique works on big pumps on ships so it should work on your tiny little pump.

andy |

|

|

|

|

|

#467 |

|

Premium Member

Join Date: Feb 2004

Location: Round Rock, TX

Posts: 1,620

|

Wow. I started this thread originally (before it split) back in 2005...and it's still going!

My H&S was still going strong up until I tore down my tank a couple years ago. Never had any real problems with it either. For your o-ring problem...if some silicone grease doesn't do the trick (and you're in a pinch and can't find a new one) - try wrapping some teflon tape around the o-ring to make it a little thicker. I had to resort to doing this one time and it worked great.

__________________

Everyone has an opinion. Accept the fact now that someone isn't going to like yours sooner or later. Current Tank Info: 110g in-wall, ATI 8x54w T5, 2xMP40es, SRO XP-2000i, 2-part Ca/Alk, Apex controlled |

|

|

|

|

|

#468 | |

|

Registered Member

Join Date: Jan 2003

Location: Costa Mesa, CA

Posts: 366

|

Quote:

Wouldy you happen to have pics on your skimmer plumbing as described above? I am just not a handyman on the plumbing. My tank has two drains so I am planning to use one of the drains to feed my skimmer direct and install a ball valve. H&S Fins Reef told me that I need a flow of 300GPH to feed skimmer. Thanks again. Mike Last edited by nguyenmi; 03/03/2011 at 01:06 PM. Reason: Correction |

|

|

|

|

|

|

#469 |

|

Registered Member

Join Date: Mar 2003

Posts: 1,133

|

If you got dual drains your golden. Just put a ball valve in line and feed direct to your skimmer. Thats much simpler then what I'm forced to do with a single drain.

Oh I have no pix. Nearly impossible to take pix cuz theres just no room behind the tank and my lens isnt wide angle enough. andy |

|

|

|

|

|

#470 |

|

Registered Member

Join Date: Jan 2003

Location: Costa Mesa, CA

Posts: 366

|

So I do not need a T correct? Just plumb direct from overflow to skimmer with a ball valve?

|

|

|

|

|

|

#471 |

|

Registered Member

Join Date: Dec 1999

Location: Amish Country, PA. USA

Posts: 978

|

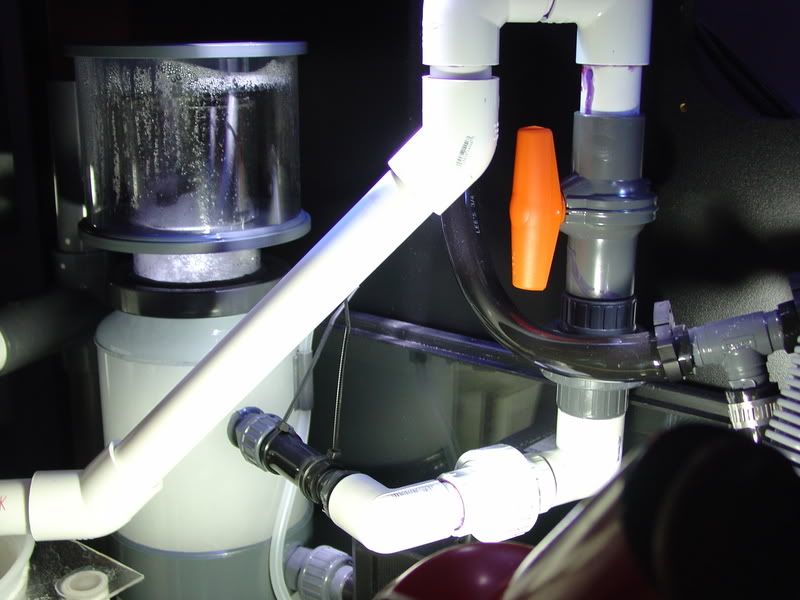

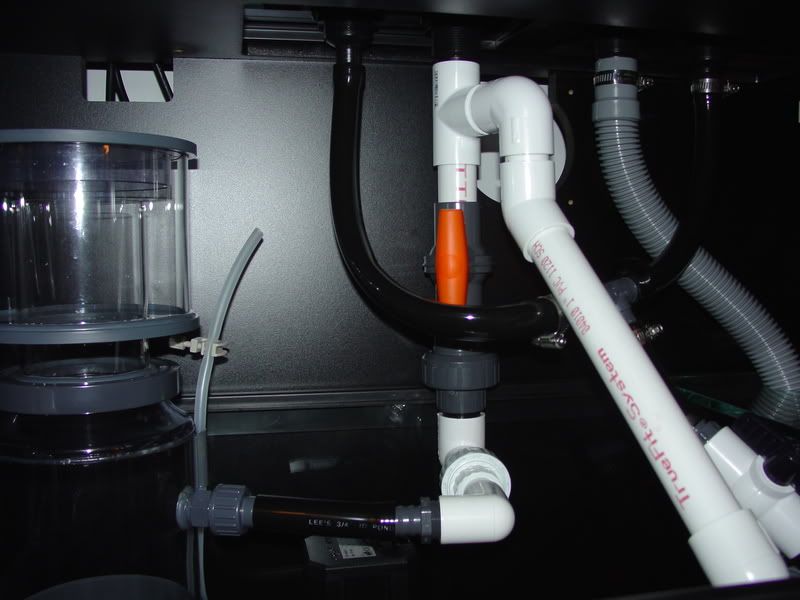

Here's how I have my A150 plumbed......

[IMG]  [/IMG] [/IMG][IMG]  [/IMG] [/IMG]Joe

__________________

I put the laughter in slaughter. Current Tank Info: 120 Gallon Oceanic Tech Tank, Two MP40W Gen 2 Vortechs, H & S A-150-F2001 External Skimmer, Oceanic Model 3 Sump, Current Outer Orbit Pro 250 Watt MH/T5 Combo Last edited by Joe; 03/03/2011 at 01:49 PM. |

|

|

|

|

|

#472 |

|

B'rer Reefer

Join Date: Jan 2001

Location: Greenwich, CT

Posts: 3,194

|

Does anyone still have any of the ceramic washers for sale or is anyone going to place another order soon?

__________________

Be Kind To The Elderly. Life Without Parole Means Nothing To Us. ToTM 3-03 Current Tank Info: Between tanks. Searching for a home |

|

|

|

|

|

#473 |

|

Registered Member

Join Date: Feb 2004

Location: Wallingford, CT

Posts: 4,990

|

I just pulled my 2 pumps apart to install the ceramic washers and one impellar magnet got pretty chewed up.

I highly suggest people with the eheim pumps with SS washers change them out. |

|

|

|

|

|

#474 |

|

Registered Member

Join Date: Jan 2007

Location: menifee So cal

Posts: 11,042

|

Thanks for the recommendation, I was running my Eheim in vinegar and I noticed my water was 95 degrees in the 5 gallon bucket, I checked my impeller and the SS washers were all chewed up. Just put some new ones in will see how they work out.

|

|

|

|

|

|

#475 |

|

Registered Member

Join Date: Jul 2009

Location: Spokane, WA

Posts: 316

|

|

|

|

|

|

| Thread Tools | |

|

|