|

|

|

|

#201 |

|

Registered Member

Join Date: Aug 2015

Location: Poland

Posts: 652

|

"Lot of gas/carbon dioxide"

|

|

|

|

|

|

#202 | |

|

professional snow flake

Join Date: Jan 2005

Location: Riverside, Cali

Posts: 5,962

|

Quote:

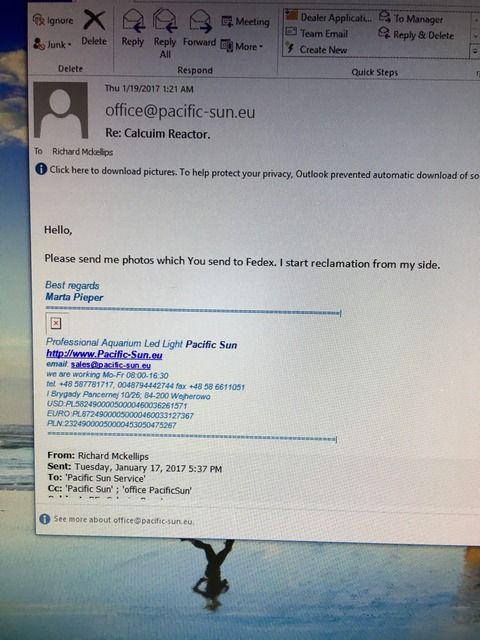

Przemek, it appears to me that there is some major communication errors here. not once did you or anyone ask me for pictures of the box. here is an example of this.  I am beyond disappointed that this arrived broken believe me I was very excited to have the opportunity to get this. Now after the fact this is a complete nightmare and I will never order anything like this again. As I was concerned it may leak after me trying to repair it. Well it leaks in other places due to the rough handling from FEDX. I know this is not my fault or yours but me the customer is out of a lot of money for this regardless of what I paid. sure you sent out replacement parts some being the wrong ones on your dime or euro but I am the customer here that is now without a product that I can not even use.  another photo a few moments later.  this is just running water thru it and no pressure via Co2 I would imagine it would leak even more under pressure and then sooner or later the entire seam may break and probably causing some fire in my home. I bought this unit to assist me with my aquarium and not give me nightmares. Anyone want to buy a calcium reactor that is new only has had water run thru it and willing to buy at own risk send me a PM. This unit is absolutely will never go on my tank and now out a lot of money.

__________________

Richard Current Tank Info: 450 gallon peninsula tank 72*48*30 filled with a bunch of frags and trying to grow them out. Last edited by Dino; 03/31/2018 at 10:38 AM. |

|

|

|

|

|

|

#203 |

|

Registered Member

Join Date: Aug 2015

Location: Poland

Posts: 652

|

Dear Richard,

I saw on mail that you sent missed photos - thank you. From our side we will want to get anything from Fedex regarding that damage now but probably it's too late.. But we don't want to continue that case longer, we stay behind our products and even if it will be completely our loss we will replace that reactor on our cost. My support team will contact with you regarding that procedure. You will get new reactor and after that we will think what we can do with that actual one. I hope that this solution will satisfy you and past things will be forgotten - we really try to do our best taking care about Customers before and after sale. That time not all things goes on our mind - hope that will never happen again. I want to apologise for that situation. thank you for cooperating and I hope that you not lost trust in Pacific Sun brand. Sincerely, Przemysław Cybulski |

|

|

|

|

|

#204 | |

|

professional snow flake

Join Date: Jan 2005

Location: Riverside, Cali

Posts: 5,962

|

Quote:

Talk to you soon and Thanks again. Richard.

__________________

Richard Current Tank Info: 450 gallon peninsula tank 72*48*30 filled with a bunch of frags and trying to grow them out. |

|

|

|

|

|

|

#205 | |

|

Registered Member

Join Date: Mar 2007

Location: Las Cruces, New Mexico

Posts: 795

|

Quote:

|

|

|

|

|

|

|

#206 |

|

Registered Member

Join Date: Aug 2015

Location: Poland

Posts: 652

|

Please send it again, we have 100% emails replied (mostly in the same working day) - maybe they not received it .

|

|

|

|

|

|

#207 | |

|

Registered Member

Join Date: Apr 2002

Location: Orange, CA

Posts: 9,666

|

Quote:

__________________

Greg Carroll I will be at REEF-A-PALOOZA! SPS = Stability Promotes Success Be wary of advice coming from those who will not show you the fruits of their success! Current Tank Info: building: 250g AGE Euro tank, Abyzz A200, Vertex Supra-G filtration, Ecotech Radion Pro LEDs, ... |

|

|

|

|

|

|

#208 | |

|

Registered Member

Join Date: Mar 2007

Location: Las Cruces, New Mexico

Posts: 795

|

Quote:

|

|

|

|

|

|

|

#209 | |

|

Registered Member

Join Date: Mar 2007

Location: Las Cruces, New Mexico

Posts: 795

|

Quote:

|

|

|

|

|

|

|

#210 |

|

Registered Member

Join Date: Jul 2010

Posts: 284

|

Will Pacific sun be posting any videos of this reactor running maybe even some tutorials on the water level in the mixing chamber just things of that nature?

__________________

New Hampshire USA Current Tank Info: 500 Gallon display tank 200 gallon basement sump |

|

|

|

|

|

#211 |

|

Registered Member

Join Date: Mar 2001

Posts: 1,869

|

Yes, some instructional videos would be great. I'm interested in purchasing but don't feel like I understand it well enough yet.

|

|

|

|

|

|

#212 |

|

Registered Member

Join Date: Aug 2015

Location: Poland

Posts: 652

|

We can prepare movie showing mixing chamber however setting it should be really not so hard.

Most important key is completely filling both chambers with aquarium water (during setup) and properly close it(tightening screws to prevent any air sucking from outside). After that Customer need to adjust co2 flow from bottle on 1-3 bubbles per second output - and connect it to proper port on reactor(Co2 Input) thru included in set solenoid valve. Thats all. When controller is powered on it slowly start filling mixing chamber with carbon dioxide. If in first "round" it will not reach requested level - controller should be restarted(using menu - then Reset button) - and cycle will start again. When CO2 will reach proper level in mixing chamber - reactor will start working and nothing more(than adjusting effluent output) have to be done.. PS. We don't want to publish too much details on website, it took us almost a year of experiments to have everything properly designed/assembled(chamber diameters/flow speed, size and height internal column details etc...) But simply movie showing mixing chamber during work is of course possible ;-) |

|

|

|

|

|

#213 |

|

Registered Member

Join Date: Jul 2010

Posts: 284

|

i just seem to be chasing my alk levels i am currently at 7dkh using a API test kit, i currently have output of effluent at 2.725 L/HR and actually raised it to the current setting of 3.200 L/HR and keep testing every 12 hours.just when i think i have the effluent set right i will test and dkh is usually in the 7-7.5 range. i guess i will just keep testing and raising the L/HR effluent up higher and see what happens.

__________________

New Hampshire USA Current Tank Info: 500 Gallon display tank 200 gallon basement sump |

|

|

|

|

|

#214 |

|

Registered Member

Join Date: Jul 2010

Posts: 284

|

is the arrow on this knob suppose to be set at wide open? or do we adjust this? it seems adjusting it with raise water level in co2 chamber which also cuts down on all the big bubbles in that same chamber.

__________________

New Hampshire USA Current Tank Info: 500 Gallon display tank 200 gallon basement sump Last edited by Dino; 03/31/2018 at 10:38 AM. |

|

|

|

|

|

#215 |

|

Aquaholic

Join Date: Jun 2002

Location: Somewhere

Posts: 800

|

I don't even have that knob on mine^

This thread is making me want to not even set this thing up!! I may keep watching and keep it dry until someone has some positive results since I haven't seen any yet. |

|

|

|

|

|

#216 |

|

Registered Member

Join Date: Aug 2015

Location: Poland

Posts: 652

|

This valves are only in AC3 and AC4 reactors because they are using strong circulation pumps. Depending from media size and capacity - sometimes it's needed to adjust valve to prevent sucking carbon dioxide by pump from reaction chamber .

Important thing - please be sure that calcfeeder pro controller pump is not pumping water with air bubbles (which can happened if water is taken from first sump chamber where it's overflowing from aquarium - many times with micro bubbles . That bubbles will "take place " of carbon dioxide in reaction chamber - and ph will in effluent will slowly grow up. Usually , depending from media and reactor type ph in effluent (before degassing chamber) should be about 6.3-6.5 not higher . If it's higher - mean that in reaction chamber there is no only co2 - but also atmospheric air taken by pump during feeding reactor process. Please control it when you need to unexpectedly increase cdlcgeeder flow without any important aquarium changes(additional corals in tank etc) |

|

|

|

|

|

#217 | |

|

Registered Member

Join Date: Jul 2010

Posts: 284

|

Quote:

__________________

New Hampshire USA Current Tank Info: 500 Gallon display tank 200 gallon basement sump |

|

|

|

|

|

|

#218 |

|

Registered Member

Join Date: Jul 2010

Posts: 284

|

Just checked my alk in display tank and of course it's back down to about 7.5.... at the same time I checked the ph of the effluent coming out of the reactor was running 7.1 two days ago it was 6.5? I don't think there is any air getting into the reactor, I have two which runs to controller from some in a spot where there's absolutely no bubbles so no air pockets can get in through the input going into controller. I'm getting very very frustrated, just when I think I may have it I don't. I don't know what else to do but keep playing around until I try to get it figured out.

__________________

New Hampshire USA Current Tank Info: 500 Gallon display tank 200 gallon basement sump |

|

|

|

|

|

#219 |

|

Registered Member

Join Date: Aug 2015

Location: Poland

Posts: 652

|

Hi Rob

This reactor is quite simply in construction and only one change in compare to regular version is fact that it use optical sensor to co2 measure in mixing chamber. Co2 is gas which can completely dissolve in water - so if you are getting higher ph in effluent than initially it mean that some gass in reactor is also air not only carbon dioxide. You need to check tubing connection and union fittings - they should be tightened and PE tubings putted to the end(to prevent sucking "left" air). Also other common issue is not completely tightened cap of mixing chamber (there is under pressure effect) which can cause sucking air from outside of reactor. If reactor is not leaking - there is no other way. So please check all above and if it will not help -please contact with our support.(you can check also your alkalinity level in effluent- depending from media it should be about 70-80 dKH http://blog.coralwonders.com/en/calcfeeder/ |

|

|

|

|

|

#220 | |

|

Registered Member

Join Date: Jul 2010

Posts: 284

|

Quote:

__________________

New Hampshire USA Current Tank Info: 500 Gallon display tank 200 gallon basement sump |

|

|

|

|

|

|

#221 |

|

Registered Member

Join Date: Jul 2010

Posts: 284

|

__________________

New Hampshire USA Current Tank Info: 500 Gallon display tank 200 gallon basement sump |

|

|

|

|

|

#222 |

|

Registered Member

Join Date: Jul 2010

Posts: 284

|

i get no bubbles in the reactor with this blue line closed all the way like it is in this photo, but when its closed there are lots of bubbles if this blue valve is open all the way like bubbles in vid

__________________

New Hampshire USA Current Tank Info: 500 Gallon display tank 200 gallon basement sump |

|

|

|

|

|

#223 |

|

Registered Member

Join Date: Jul 2010

Posts: 284

|

this is how it runs with that blue valve ( co2 reflow) vale closed notice no bubbles entering media reactor chamber but the water level in co2 chamber will rise causing error message on controller. i am sorry for all the questions but like i said i am very very frustrated trying to figure this out....... PLEASE HELP!!!!!!!! this is a very expensive piece of equipment.

https://www.youtube.com/watch?v=LV45...ature=youtu.be

__________________

New Hampshire USA Current Tank Info: 500 Gallon display tank 200 gallon basement sump |

|

|

|

|

|

#224 |

|

Aquaholic

Join Date: Jun 2002

Location: Somewhere

Posts: 800

|

Is that normal?

Seems loud I can tell u this mine is for sale if that's really the noise to be expected. |

|

|

|

|

|

#225 | |

|

Registered Member

Join Date: Jul 2010

Posts: 284

|

Quote:

__________________

New Hampshire USA Current Tank Info: 500 Gallon display tank 200 gallon basement sump |

|

|

|

|

|

|

|