|

|

|

|

#1 |

|

Registered Member

Join Date: Mar 2008

Location: Edmonton,Ab

Posts: 30

|

aqua safe RO unit

i bought this unit and the directions arent very clear could someone send me a picture of how theirs is set up please.

Thank-you. |

|

|

|

|

|

#2 |

|

Registered Member

Join Date: Apr 2008

Posts: 26

|

how many chambers do you have? what model is it? that will probably help, i dont have your brand but i do have a RO/DI.

|

|

|

|

|

|

#3 |

|

Registered Member

Join Date: Dec 2006

Location: Saskatoon, Sk, Canada

Posts: 28

|

Oh man, your telling me. The directions absolutely suck, just horrible. I had a plumber set it up though, which did cost a lot. I have the home unit, which is great for what it is, I have the TDS readings at 10 which is a 95% rejection rate. I will have to get a vertical DI canister to get my TDS readings at 0 or very close to that and will probably get that from The Filter Guys. I'm at work right now so can't take a pic, but hopefully I could tomorrow.

|

|

|

|

|

|

#4 |

|

.Registered Member

Join Date: Sep 2006

Location: Cincinnati, Ohio

Posts: 4,857

|

Let me know which system you have and I can send you directions for one of our systems.

Russ |

|

|

|

|

|

#5 |

|

Registered Member

Join Date: Oct 2002

Location: Edmonton AB

Posts: 2,269

|

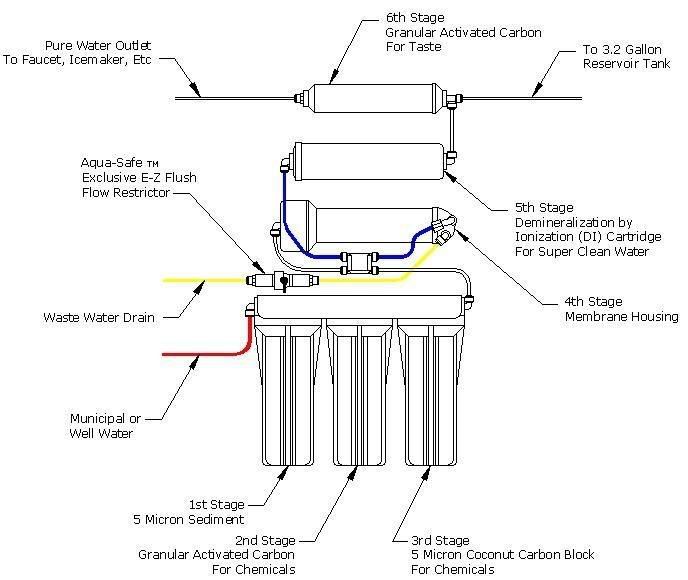

from Aqua-safe

|

|

|

|

|

|

#6 |

|

.Registered Member

Join Date: Sep 2006

Location: Cincinnati, Ohio

Posts: 4,857

|

For starters, don't run your DI water through a GAC stage (your final stage). Wehn the water comes out of the DI stage it is as clean as your system can make it.

Next, unclip that horizontal DI stage and orient it vetrically with bottom up flow. Don't store DI water in a pressure tank. Install a pressure gauge add on kit if you want to better understand if you have enough pressure to run the system, and when your prefilters need to be changed. When your prefilters need to be replaced, get rid of (don't replace) the vertical GAC stage. Use a single high quality carbon block instead of what you have in stages 2 and 3 now. Do you have chloramines in your water? If so, we'll change our recommendation a bit. Russ |

|

|

|

|

|

#7 |

|

Registered Member

Join Date: Oct 2002

Location: Edmonton AB

Posts: 2,269

|

The final GAC is included as unit is basically for drinking water, know most remove it.

Why not the reservoir, I find it really handy if I'm adding supplement such and Ca or Mg and want the dissolve in a litre of water before adding to the new SW mix. I just Tee'd a pressure valve between the unit and supply when setting up to see if I should adjust the regulator and just left it there, where should it be placed and how do you suggest it be used? Chloramines seem common at least up here, what's different? |

|

|

|

|

|

#8 |

|

Moved On

Join Date: Jan 2002

Location: NW Phoenix

Posts: 16,621

|

Storing water in a pressure tank with a rubber bladder with build up TDS as DI water is very agressive and will leach things out of other materials. Also using a pressure tank leads to short cycling or lots of starts and stops to keep the small tank pressurized. This leads to TDS creep issues which is common with all membranes on start up. A membren will produce a slug of high TDS water each time it first starts and you will be concentrating it in the pressure tank and wearing out your DI resin very quickly. You want long constant runs for best water quality not short spurts.

|

|

|

|

|

|

#9 |

|

.Registered Member

Join Date: Sep 2006

Location: Cincinnati, Ohio

Posts: 4,857

|

Good points all. You also typically have contact with metal on a pressure tank.

Russ |

|

|

|

|

|

#10 |

|

Registered Member

Join Date: Oct 2002

Location: Edmonton AB

Posts: 2,269

|

This TDS creep I keep hearing about how much is it?

I've been running a float valve in my sump for ATO connected directly to the ro/di unit for years. My output TDS isn't zero but always in the low single digits which I think is fine (specially considering the 12 cups of salt mix I use every 2-3 weeks and whatevers in that). After about 8-10 months I'll notice a slight rise, replace my filters and resin (which I keep been meaning to in 6 month intervals anyways) and the TDS drops again to the low single digits. This slug of high TDS water, is it the TDS of the incoming source water? Guess I'm being somewhat argumentative but I've never seen it. Meter seens okay; when I've measured source water seems in-line with what's published by Utility, on the output from the Di reads near zero. To measure I'll run a few oz into a cup so it's deep enough for the probe, is it that this slug is only the first 1/2 oz so I'm missing it? Is it that TDS of the water provided from the Utility here is usually under 300 (closer to 225 on average)? |

|

|

|

|

|

#11 |

|

Moved On

Join Date: Jun 2006

Location: germantown,wi

Posts: 2,339

|

The TDS creep is a slug of higher TDS water on the out put of the RO unit from the memmbrane, most likely your DI is picking it up, but does contribute to exhausting your DI sooner.

|

|

|

|

|

|

#12 |

|

Moved On

Join Date: Jan 2002

Location: NW Phoenix

Posts: 16,621

|

It starts as high as the tap water TDS or even higher as it can be the concentrated waste surrounding the membrane. It does not last for long but it has a very big effect on the life of your DI resin. There are "pass to drain" conversions available that flow to waste on start up so that initial slug does not hit the DI resin. It may or may not be cost effective for everyone depending on your water quality, how often and how much water you make.

One huge advantage of the new Spectrapure MaxCap UHE system I recently switched to is it backflushes the membrane with DI water based on a program in the microprocessor and keeps the membrane surrounded by DI when it is shut off so you don't have that slug of high TDS water on the membrane all the time. Again it is expensive but you get what you pay for. I fully expect my RO membrane to last 7 years or more even at a 1:1 waste ratio or less and Phoenix AZ 800-1200 TDS tap water. |

|

|

|

|

|

#13 | |

|

Registered Member

Join Date: Oct 2002

Location: Edmonton AB

Posts: 2,269

|

Quote:

Guess I'll live with changing out 5 bucks of resin every 8 months. |

|

|

|

|

|

|

#14 |

|

Moved On

Join Date: Jun 2006

Location: germantown,wi

Posts: 2,339

|

You cannot compare TDS from your unit, to your salt mix, salt is a disovlved solid and all the trace elements, "total dissolved solids",

those are good TDS, but what is getting past the DI may not be, usually amonia is the first to get release from the DI resin when outletlet TDS get above 1-2. |

|

|

|

|

|

#15 |

|

Moved On

Join Date: Jan 2002

Location: NW Phoenix

Posts: 16,621

|

Ammonia, phosphates, silicates and nitrates are 4 things DI does not handle well due to being weakly ionized. Change your resin immediately when you first start to see anything other than a constant 0 TDS.

|

|

|

|

|

|

|