|

|

|

|

#1 |

|

Registered Member

Join Date: Sep 2008

Location: Utah

Posts: 124

|

Matching return and drain flow rates

I am setting up a new 75 gallon with corner overflow. I have a mag 12 return pump with 3/4 inch pipe and my drain is T'd off...half going goind to refugium and other half to sump. The flow to both is controlled with ball valves. I am having a very hard time getting the water level in the tank right. Does anyone know any tricks to get it right?

|

|

|

|

|

|

#2 |

|

Space is big.

Join Date: Feb 2007

Location: Maryland Eastern Shore

Posts: 3,226

|

What size drain pipe are you using? Do you have a valve on the return line?

The pump should only be pushing as much water and preferably less then what the overflow can handle. If you tee off the drain pipe, one line should be totally unrestricted to allow any water not going to say the refugium to go to the sump directly. Drain lines should never be restricted as this will lead to a flood. Maybe not today, maybe not tomorrow, but eventually, it will. Another thing, you need to make sure the system is designed to handle a power outage without any outside assistance such as check valves. All it takes is a small snail over a hole or in a valve and its no longer functional. Hope that helps. RocketEngineer

__________________

-RocketEngineer "Knowledge is what you get when you read the directions, experience is what you get when you don't." - Unknown Current Tank Info: None Currently |

|

|

|

|

|

#3 |

|

Registered Member

Join Date: Dec 2005

Location: capitola ca

Posts: 1,729

|

The tank needs an overflow box. It is a very bad idea to restrict your drains , if anything you could restrict your pumps output . Without an overflow box or your drains at the hieght you want your water level in the tank to be , you will never keep a balance because things are always changing.

|

|

|

|

|

|

#4 |

|

Moved On

Join Date: Mar 2008

Location: Spokane, WA

Posts: 3,263

|

Most will tell you not to place a valve on your drain unless only on one side of a split, otherwise one valve can become clogged and your DT will spill over. Tho depending on your setup, the total risk in gallons might be very limited. I back the waterline up the drain pipe to my overflow without problem and risk only half a gallon of spillage should a clog occur. This is acceptable to me as it helps reduce the noise and bubbles created by a waterfall in the tube. This can't typically be accomplished with ball-valves however. I use a ball-valve on my primary drain and a gate-valve on my fuge drain. I use the ball-valve to get the general flow I want, then use the gate-valve to fine tune the water level in my overflow box.

If you do use this system, be sure to keep the waterline in your overflow-box BELOW the overflow teeth, as this creates maximum draw on the waters surface, removing surface scum and buildup. Otherwise, you'll see that scum float into the overflow only to then float right back out. Keep it below the teeth for a clean surface. |

|

|

|

|

|

#5 |

|

Registered Member

Join Date: Nov 2008

Location: Hampton, Va

Posts: 104

|

+1 for the rocket scientist,,would'nt suggest restricting your flow by use of ball valves or anything for that matter, the ball valves are best used on the return lines not the feed lines. Depends on your overflow but should be around 600 gph feeding out of your tank and your using a 1200 gph pump on the return, move the ball valves and adjust the return to equal the amount thats being fed, turn off your system and check to see if it equals out without overflowing your sump.

|

|

|

|

|

|

#6 |

|

Registered Member

Join Date: Sep 2008

Location: Utah

Posts: 124

|

Thanks everyone. I have a 1 inch drain line and no valve on the return. I have been trying to find that sweet spot where the water is going into the overflow just below the top of the teeth. I am going to leave the drain into the sump unrestricted and then only use the valve leading to the refugium...maybe replace it with a gate valve for fine tuning. Then I will add a valve to the return line to restrict it's flow. How does this sound?

Also, I will test to make sure the sump/refugium will not overflow in case of power outage. |

|

|

|

|

|

#7 |

|

Registered Member

Join Date: Nov 2008

Location: Hampton, Va

Posts: 104

|

sounds like a plan,,when your finished you will see how easy it is,,,,even a rocket scientist can do it lol

|

|

|

|

|

|

#8 |

|

Registered Member

Join Date: Sep 2008

Location: Utah

Posts: 124

|

sassafrass, what do you mean by my tank needs an overflow box?

|

|

|

|

|

|

#9 | |

|

Moved On

Join Date: Mar 2008

Location: Spokane, WA

Posts: 3,263

|

Quote:

Good luck with it.

|

|

|

|

|

|

|

#10 |

|

Registered Member

Join Date: Jul 2008

Location: Kitchener, ontario

Posts: 244

|

birch, I think I know where your problem lies. Apparently you are not using an overflow box, which believe me, helps tons. I think you may be using a simple bulkhead with a stainer on it. Am I correct? If so,

the first thing you need to look at is a flow calculator for drain lines.(google my friend, google, they are there). 1" drain I believe is 600GPH. Then there are two ways to solve the problem you have right now. 1ST being an overflow. They will help to control the water level and is much easier, and the fine tuning. The second is to install the valve for the restriction. With that much extra power that you have, I would "T" off the return, right after the pump, then add the ball valve on the "T" and dump it in the sump, so you can use it for more control. The plus side to doing the dump gate method is to provide flow in your sump which will help against the skunky build up on the water surface in that area. Last edited by Klaus777; 12/23/2008 at 04:06 PM. |

|

|

|

|

|

#11 |

|

Registered Member

Join Date: Sep 2008

Location: Utah

Posts: 124

|

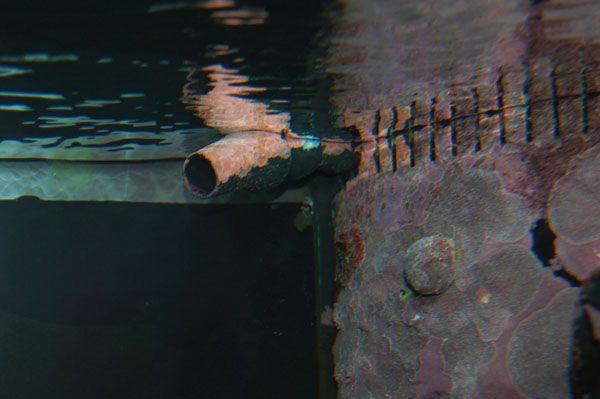

Thanks for the advice everyone, but I think I have caused confusion and need to clarify. I have a reef ready tank that has a corner overflow box. I am trying to get the water level in the overflow right so that it is high enough to keep up with the drain. I also have a small hole drilled in the PVC elbow at the top of the return line where it shoots back into the tank (to break the siphon in the event of a power failure. If this hole is above the water line the water that sprays out of it makes a loud noise and I want to stop this. Any ideas?

After a lot of thinking and reading thru the comments, I think this 'hole' placement is the problem...but I am still going to fix my drain and return as recommended...I want to do things right. Sorry again for the confusion and thanks. |

|

|

|

|

|

#12 |

|

Moved On

Join Date: Mar 2008

Location: Spokane, WA

Posts: 3,263

|

Tho I use an atypical system similar to what you were first attempting, typically the water level in the overflow box is purely dependant upon the height of the drain hole. It really shouldn't have a water level per say other than where it drains into the drain pipe.

How low does your overflow-box water level go exactly? |

|

|

|

|

|

#13 |

|

Moved On

Join Date: Mar 2008

Location: Spokane, WA

Posts: 3,263

|

Add a PVC elbow to the drain inside the overflow-box and turn it upward. Then add PVC tubing to reach the desired height.

Hope that helps, and good luck. |

|

|

|

|

|

#14 |

|

On Yer left!

Join Date: Sep 2004

Location: Northern VA

Posts: 18,777

|

Dont worry about the height of the water on the teeth. It is where it is. As long as the return flow is less that the maximum capacity of the overflow/drain, it works.

Have the standpipe height in the overflow so that the water falls just an inch or so to minimize noise, but still provide surface skimming. Ditch the siphon break hole. Its not needed if you set up your return the right way. Position your return outlet so that it is just below the surface. This is much more reliable than a drilled siphon break hole.

__________________

- Scott |

|

|

|

|

|

#15 |

|

Registered Member

Join Date: Sep 2008

Location: Utah

Posts: 124

|

Everyone, thanks a ton for all the advice. I understand everything clearly now. I am ditching the drilled hole and setting up my return lock line similar to sjm817, and I am making the necessary changes to the valves on the drain and return. Merry Christmas!

|

|

|

|

|

|

#16 |

|

Space is big.

Join Date: Feb 2007

Location: Maryland Eastern Shore

Posts: 3,226

|

For clarification, I am NOT a rocket SCIENTIST. I am a rocket Engineer. I don't do any science, I make sure the scientist's sensors survive launch and get where they need to be.

Glad to help. Happy Holidays Everyone.

__________________

-RocketEngineer "Knowledge is what you get when you read the directions, experience is what you get when you don't." - Unknown Current Tank Info: None Currently |

|

|

|

|

|

#17 |

|

Retired Rebel Reefer

Join Date: Sep 2005

Location: Triad NC

Posts: 1,902

|

I think this has been said but I'll reinforce it again. Don't try and control your flow by restricting the return, restrict the flow until you get a level in the overflow box that you are happy with.

Also ball valves are not good at fine tuning a flow - use a gate valve for that purpose. Happy Christmas to everyone.

__________________

Alan "Never in the field of human conflict was so much owed by so many to so few. " Sir Winston Churchill praising those young RAF pilots. August 20th 1940 Click on my name for drop down list and select "Visit EnglishRebels Home Page" for my build thread. Current Tank Info: 60x30x24 200G AO custom glass tank, basement equipment room, 30G and 55G Fuges, LifeReef sump & 30" skimmer. |

|

|

|

|

|

|