|

|

|

|

#1 |

|

Registered Member

Join Date: Sep 2014

Posts: 9

|

Seeking input on new tank setup

I've never posted to this forum before but i have lurked for awhile in the shadows and have tried to learn and use information i gained from this site.

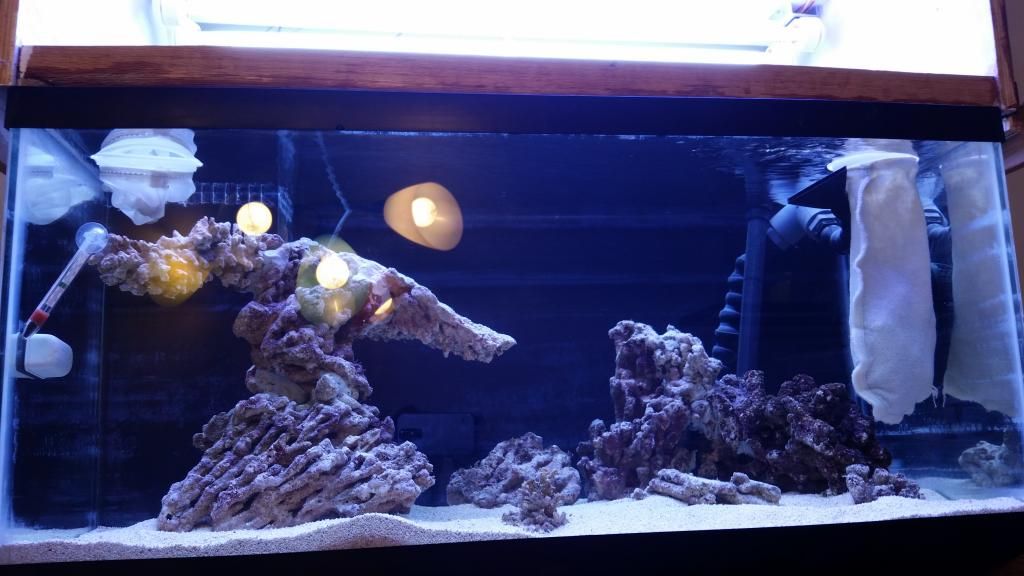

I started a rebuild of my tank (40B with 20L sump) after i had a ATO overflow issue. I decided i wanted to place a tarp under the tank to protect the floor from minor drips and splashed and try to improve the filtration in my sump. At the same time i figured i would change up my rockwork and and sand to the bottom. I have been running my tank barebottom for 3 years until now and i really miss the look of sand. Also I really like diamond gobys and wanted to have sand so i could have one. [IMG]  [/IMG] [/IMG][IMG]  [/IMG] [/IMG]Anyway I have been cycling the tank for a week now and I'm not sure i like the way i set up the sump. My skimmer has been producing lots of microbubbles that it never produced before. The water level is higher than before but i thought i could stop any bubbles by adding baffles. On my last sump i just had a very short 4 inch baffle coming from the bottom to prevent any rubble rock from getting too near the return outlet, and i never had an issue with the microbubbles before. [IMG]  [/IMG] [/IMG]I have a t coming off my return going to two outlets with stop valves. I am planning on adding a 10 gallon fuge to the system and supplying it with one of these outlets and the other is for either a UV unit or some type of media reactor. also there is a T that sends water back into the sup that I don't want going to the display so i can fine tune flow in the display without ever throttling my pump.  I am looking for any feedback that anyone wants to give. Don't pull any punches. |

|

|

|

|

|

#2 |

|

Registered Member

Join Date: Sep 2014

Posts: 9

|

Nobody has any thoughts? I found my skimmer pump is leaking microbubbles from the impeller cover. I'm getting a new one ring to stop that today. But I'm still getting just a ton of bubbles from the water outlet that the foam ring around the outlet cannot seem to stop.

|

|

|

|

|

|

#3 |

|

Moved On

Join Date: Sep 2014

Location: Oceanside, CA

Posts: 68

|

If you have micro bubbles, it's likely you have a leak or you have bubbles getting through your baffles and being sucked up by the return and spit into the display.

And....why are there filter socks in your DT!!!! Get those ugly things in the sump. :-) |

|

|

|

|

|

#4 |

|

Space is big.

Join Date: Feb 2007

Location: Maryland Eastern Shore

Posts: 3,226

|

1) The system hasn't been running long enough to develop a slime coat on all the surfaces which is one of the reasons microbubbles are present. Given time, this normally goes away on its own.

2) The standpipes in your overflow are very short which means the water is falling several inches down the inside of the box. If you install taller standpipes then the falling water has less momentum and therefore is less able to entrain bubbles into the flow. Also, the drains should be straight down or use 45s to jog over. The horizontal run on the siphon line isn't recommended. Not a big deal, just not best practices. 3) There is currently no way for you to remove the return pump for cleaning without draining the sump. The way you have the pump inlet is highly restrictive and may be causing cavitation issues. 4) I would bet that your return pump is running full speed because there is no back pressure. The tee you have draining back into the tank just wastes energy for no gain. The pumps we use are designed to work against pressure from plumbing so you would have been better off if you had placed the gate valve in the return line instead of running it back to the sump where it does nothing. Combine Items 3 & 4 and you get cavitation bubbles which will ultimately ruin your pump. As Reeflo is no longer making that kind of pump, you would do well to reconsider your return plumbing.

__________________

-RocketEngineer "Knowledge is what you get when you read the directions, experience is what you get when you don't." - Unknown Current Tank Info: None Currently |

|

|

|

|

|

#5 |

|

Registered Member

Join Date: Feb 2014

Location: Foothills of SC

Posts: 2,010

|

Yeah. What he said^^^

__________________

120 gal mixed tank. Lightly stocked now but.... |

|

|

|

|

|

#6 |

|

Registered Member

Join Date: Sep 2014

Posts: 9

|

Thanks for the suggestions. Let me clarify some things and ask for clarification on others.

Point 1. Makes sense. So should i just leave the skimmer running and let all the microbubbles happen for as long as they happen? Point 2. I know that 90 degree elbows are never the best choice but i am working in limited space so i have done what I could in the space i have. Good point on the large drop in the overflow causing bubbles. I can see them from across the room. But these bubbles will all get routed to a filter sock so they don't really move through the rest of the sump. Point 3. I had set up the return pluming with the ball valve so i don't have to drain the sump if i need to service the pump. The pump is connected via unions on both sides so i can remove it for cleaning if needed. I do see now that there will be water in the pipe upstream of the pump but i think if i place a tray underneath the union when i take it apart i could catch most of the water without issue How could i fix the returns inlet so it is less restrictive? Is it the 90 degree elbow you are talking about? If so is it the one inside the tank or the one right before the pump? I can completely remove the one inside the tank very easily. What do you suggest? Point 4. I actually have the pump running at the first level of its speed and it has three levels. I figure when i set up the refugium and any media reactor i can crank it up a notch and then utilize the pressure relief. I thought that having too much pressure on the output of a pump could shorten its lifespan. Previously i had the gate valve directly after the return pump that only went to the display. I didn't have any problems then but I remember reading something that suggested that throttling a pump like that could decrease its lifespan. Again thank you for your response. I am not trying to contradict you with my post, just trying to display my thought processes and try to better understand what I should do. Thanks |

|

|

|

|

|

#7 |

|

Space is big.

Join Date: Feb 2007

Location: Maryland Eastern Shore

Posts: 3,226

|

Because the tank is so new, all the little nooks and crannies in the plumbing can trap gasses and allow them to become bubbles. Once the biofilm has had a chance to grow, it cuts down on the most common places for this to happen. It may not get rid of all of them but it helps reduce them significantly.

I see now, there are connections on either side of the pump itself. I thought you were using the in line unions for that. My mistake. I'm not sure what size plumbing the pump is which will impact whether you can make it less restrictive or not. I would take the two 45s after the pump, replace them with a 90 and move the pump as far back as possible. You want a long straight run before pumps to minimize issues. Getting rid of the one in the sump is another good idea. I'm not sure where the idea that throttling a pump reduced its lifespan came from. I've seen a bunch of folks propagate the idea but there is no proof that I have found. Considering that pumps are designed to work against pressure, unless you have a pump so cut off that it doesn't move any water and overheats from lack of flow, they really are designed to run with some back pressure so they aren't freewheeling the impeller. With the Herbie drain you are capable of running quite a bit of flow through the system. I would run the return pump as fast as I could get away with with to help with turnover in the tank as well as surface renewal of the display. I don't mind polite constructive conversations. I'm far from perfect and there is a TON of stuff to learn in this hobbie. Take my word with a grain of salt, I took a 2.5 year old system and wiped it out when I upgraded to a larger tank. Even the best of us fail at times.

__________________

-RocketEngineer "Knowledge is what you get when you read the directions, experience is what you get when you don't." - Unknown Current Tank Info: None Currently |

|

|

|

|

|

|