|

|

|

|

#1 |

|

Registered Member

Join Date: May 2015

Posts: 25

|

algae turf scrubber build

I seem to be confused as to how to properly plumb my turf scrubber. I have the overflow set up and the slit drilled with the screen and stuff. Then I have the return pump sending the water back to my display tank from the sump.

How do i maintain the even water levels? It seems my pump sent to much water too quick into my display tank and the overflow could not handle it and I almost had a flood on my hands. I dont want a flood but I want to get this done right. My overflow is an Eshopps Pf-800 rated at 800GPH but obviously it does less due to the algae screen and the slit only being 1/8in wide. The overflow flows down into a 1in PVC pipe then into the slit and screen. My return pump is a danner mag 7 and has vinyl tubing connected to it for the water to get back to the tank. From pump up to display is about 32in up. Is my return pump too strong for this setup? or am I doing something else wrong? |

|

|

|

|

|

#2 |

|

Registered Member

Join Date: Jan 2014

Location: Cedar Rapids,IA

Posts: 198

|

I would use a separate pump or tee off your return pump to feed your scrubber. Sending all of your drain water from your tank through a small slit that could plug up is asking for trouble. If you are wanting to use the drain from tank you should have a secondary emergency drain if the main one through the scrubber can't handle it.

|

|

|

|

|

|

#3 |

|

Registered Member

Join Date: Jul 2013

Location: yangon,burma(myanmar)

Posts: 1,786

|

i agree with reefer roman. i run my ats with a separate pump. the flow will become even less when the algae grow on the screen and block the slit.

__________________

take it easy, pyithar Current Tank Info: 150G display, 50G sump, mixed reef |

|

|

|

|

|

#4 |

|

Registered Member

Join Date: May 2015

Posts: 25

|

So if I tee'd off my overflow box where some goes straight into the sump and then some goes to the ATS it would work you guys think? Or would the return pump still be too fast for it to handle?

|

|

|

|

|

|

#5 |

|

Registered Member

Join Date: May 2015

Posts: 25

|

What if i put a ball valve or something on the return pump as well?

|

|

|

|

|

|

#6 |

|

Registered Member

Join Date: Sep 2014

Location: Post Falls, Idaho

Posts: 251

|

I run a separate pump for mine, didn't want to restrict turnover from the sump to the tank and back again.

|

|

|

|

|

|

#7 |

|

Registered Member

Join Date: May 2015

Posts: 25

|

|

|

|

|

|

|

#8 |

|

Registered Member

Join Date: Jan 2014

Location: Cedar Rapids,IA

Posts: 198

|

The problem is your drain is being restricted by going into your turf scrubber. A mag 7 pump with a 3 foot head is only going to have about 500 gallon per hour flow at most. Your overflow should be more than sufficient. That pump is not big enough to tee off to feed the scrubber and provide enough turnover rate. I believe your best option is to run another pump in your sump to feed your scrubber. You can place the pump in the first section of your sump and feed it to your scrubber and drain it out into the same area or place scrubber in a position to drain into the next section of your sump. Either way it will receive enough nutrients in the water column to support algae growth.

|

|

|

|

|

|

#9 |

|

Registered Member

Join Date: Sep 2014

Location: Post Falls, Idaho

Posts: 251

|

My picture wont upload. ..I have a pump that feeds from my refugium into a separate container that hangs next to my sump. The container has the pvc with the slit and the screen where the water drains down and into a hose back into my sump. I have the light mounted in the box so it's an all enclosed unit.

|

|

|

|

|

|

#10 | |

|

Registered Member

Join Date: May 2015

Posts: 25

|

Quote:

|

|

|

|

|

|

|

#11 |

|

Either busy or sleeping

|

How big is the scrubber? Can you upload a picture?

You can safely feed a scrubber off of an overflow, but there are some situations where this doesn't work very safely. Using an HOB overflow box, you have additional concerns that must be addressed Back to the slot pipe, if you didn't cut it right it might be restricting flow. Also, if it just isn't long enough, you can't put more flow through it. The thing about overflow feeding a scrubber is that it comes down to what you need. If you have 500GPH actual flow, you're going to need a screen that is likely longer than 12". In order for that to be an effective scrubber, you need some height to it, say, 5 or 6". What you end up with is a 5 or 6 cube/day scrubber, which might be more than you really need. So before I assume too many things and end up backtracking, lets go back to the scrubber: How much do you feed? How big is the tank? What is the vertical head that the Mag 7 is seeing (top of water in pump chamber of sump to top of water in tank)? What size pipe or tubing is used for your pump return to the tank? This matters. How big is your sump? What size and kind of pipe did you use for your slot (1/2", 3/4", 1", etc and Schedule 40 vs 80, DWV, etc) Any pictures would really help.

__________________

Algae Scrubber Basics!!! GOOGLE "algaescrubber zoho" General Interest Forums --> Advanced Topics --> Algae Scrubber Basics (sticky) --> POSTS #3251-64 (Basics), #5206 (Cleaning), #6884 (LEDs), #729 |

|

|

|

|

|

#12 | |

|

Registered Member

Join Date: May 2015

Posts: 25

|

Quote:

My overflow has 1 inch schedule 40 going down into the pipe with the slit and screen. This is about a 3 foot drop to under my stand. My return pump has 32 inches of head from sump to top of display with clear vinyl tubing attached to an adapter off the pump that is 5/8 inch inner diameter I believe. In terms of feeding, my tank is relatively new and I just added my first two fish after cycling for about a month so yesterday, but when all is said and done I plan on having 7 to 10 fish total. When I try to upload pictures it says upload failed? If I was describing it, Overflow box has 1 inch PVC running down into a 90 degree angle into another PVC with the slit above the sump. If I just added a tee after the 90 so that some water went straight into the sump and the rest went into the slit part would that solve my problem or would that make my scrubber ineffective? |

|

|

|

|

|

|

#13 |

|

Either busy or sleeping

|

With 32" of head and a 5/8" ID hose, you're likely getting less than 500 GPH. At 36" with 3/4" ID hose and no elbows you would get 500 GPH...which is fine

How long is your slot pipe / screen? One thing about schedule 40 pipe is that as you cut the slot, the pipe wants to pinch closed. So you have to make several passes after you complete the initial cut or else it will pinch closed (a bit) in the middle. How did you cut the pipe, did you use a dremel cutoff wheel, table saw, router, etc? putting a tee above the scrubber can alleviate the flow issue, but the problem becomes that this allows for a low-resistance path away from the scrubber. So you want to maintain as much "head" above the scrubber as you can. Is this a reef-ready tank, or does the overflow come out of an external box or an HOB?

__________________

Algae Scrubber Basics!!! GOOGLE "algaescrubber zoho" General Interest Forums --> Advanced Topics --> Algae Scrubber Basics (sticky) --> POSTS #3251-64 (Basics), #5206 (Cleaning), #6884 (LEDs), #729 |

|

|

|

|

|

#14 | |

|

Registered Member

Join Date: May 2006

Posts: 2,354

|

Quote:

Further adjustments will be needed once the scrubber grows in and also when you clean it. This is a balancing act I wouldn't want to deal with but it will work. I would personally run it off of a second pump or tee off your return pump directly to the scrubber with a ball valve in between to restrict flow. With this setup the flow will be constant and will never have to balance flow coming from your DT. |

|

|

|

|

|

|

#15 | |

|

Registered Member

Join Date: May 2015

Posts: 25

|

Quote:

I used a dremel to cut it and i went over it 3 times to make sure it was even and all the way open The pipe itself is about 14 inches long and the screen is 8 long. The overflow is a hang on back. |

|

|

|

|

|

|

#16 | |

|

Either busy or sleeping

|

Quote:

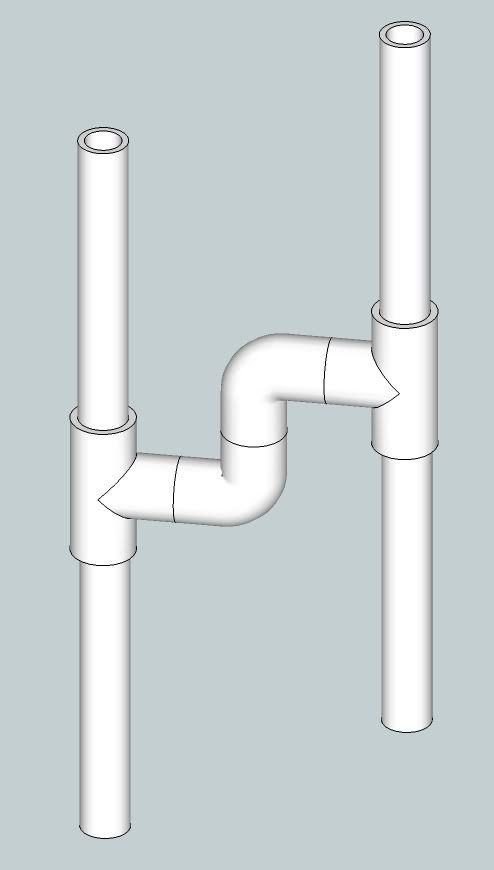

Something like this can do the trick, but it has to be configured specific to the system  The idea here is that the drain line is on the left (fed from top), bypass line on the right. When the water level backs up in the drain line due to backpressure from the scrubber, the scrubber will get more and more flow as the head increases. If the head increases enough to reach the bypass, then it flows freely down that pipe as needed. The right tee is open on the top and a pipe extends up a bit, acts as a siphon break. The right pipe is larger than the drain, so if the drain is 1" the bypass is 1.25 or 1.5". The bypass extends down just below the surface of the sump water level. This can be done with a RR tank (bulkhead in bottom of tank), what you do is put a tee under the bulkhead with the side outlet toward the bulkhead, one end of the tee goes to the scrubber and the other end goes out the back of the tank into a 90 and up along the back of the tank vertically, then you feed the drain line from the bottom (90 goes into the left pipe in the drawing above) and you can get rid of the left tee and up 90 and just go right into the left 90 and into the bypass tee. So the idea behind that is the same, as the scrubber backpressure builds up, excess flow goes up the drain pipe along the back of the tank until it hits the bypass. The downside to this concept is that it effectively reduces your maximum drain flow, so you can't have the bypass too high up. Water flow volume through a vertical drain pipe is a function of the water level difference, so as the water rises up in the pipe, the maximum flow decreases. So you have to figure out what the maximum level of the highest point of the bypass should be in order for 100% of the flow to safely go through the bypass in order to make this a truly safe bypass system.

__________________

Algae Scrubber Basics!!! GOOGLE "algaescrubber zoho" General Interest Forums --> Advanced Topics --> Algae Scrubber Basics (sticky) --> POSTS #3251-64 (Basics), #5206 (Cleaning), #6884 (LEDs), #729 |

|

|

|

|

|

|

#17 | |

|

Either busy or sleeping

|

Quote:

What model is the HOB overflow? You might be able to do something like what I show in the diagram. In your case, it would be drain into the left pipe, the bypass tee on the other side of the double-elbow. Then you just need to make the bypass tee low enough to handle all the flow without topping the tank or the HOB

__________________

Algae Scrubber Basics!!! GOOGLE "algaescrubber zoho" General Interest Forums --> Advanced Topics --> Algae Scrubber Basics (sticky) --> POSTS #3251-64 (Basics), #5206 (Cleaning), #6884 (LEDs), #729 |

|

|

|

|

|

|

#18 |

|

Registered Member

Join Date: May 2015

Posts: 25

|

Turbo what would you recommend I do? Tee the drain so there is flow straight to the sump and through the scrubber? Or tee off my return pump so it goes back to the display and to the scrubber? Or any other suggestions?

|

|

|

|

|

|

#19 |

|

Either busy or sleeping

|

Easier to tee off the return pump, as long as the HOB can handle the full flow of the return pump when you shut off the flow to the scrubber.

If you're getting 500GPH out of the return pump and you need 280 for the scrubber, that cuts your tank turnover down pretty good, but there are people who say that a low flow sump is fine if not preferred. Also you can run the scrubber at lower flow than 35 GPH/in. I ran my first one at 20-25 GPH/in and it grew algae just fine. I'm pretty sure that due to the fact that I haven't cleaned scrubber pumps in a very long time, my personal units are way under flow.

__________________

Algae Scrubber Basics!!! GOOGLE "algaescrubber zoho" General Interest Forums --> Advanced Topics --> Algae Scrubber Basics (sticky) --> POSTS #3251-64 (Basics), #5206 (Cleaning), #6884 (LEDs), #729 |

|

|

|

|

|

#20 |

|

Registered Member

Join Date: May 2015

Posts: 25

|

HOB is eshopps pf 800

|

|

|

|

|

|

#21 |

|

Either busy or sleeping

|

dang, I knew that.

__________________

Algae Scrubber Basics!!! GOOGLE "algaescrubber zoho" General Interest Forums --> Advanced Topics --> Algae Scrubber Basics (sticky) --> POSTS #3251-64 (Basics), #5206 (Cleaning), #6884 (LEDs), #729 |

|

|

|

|

|

#22 |

|

Registered Member

Join Date: May 2015

Posts: 25

|

I really appreciate your help man, thank you!

|

|

|

|

|

|

#23 |

|

Registered Member

Join Date: Oct 2002

Location: Dewitt MI

Posts: 5,051

|

I run mine running from the overflow. Here is a pic

After the 6 inch screen slit, is a 90 degree elbow and the water that doesn't go through the slit goes into the sump I have an overall flow of 800 gph so enough flow over the screen is not an issue.

__________________

Gary 180 gallon, 40 gallon sump, 3 250 W MH + 4 80W ATI T5's, MTC MVX 36 Skimmer, Apex controller Aquamaxx T-3 CaRx Current Tank Info: A 2 Barred Rabbitfish, Red Head Salon, Yellow/Purple, McMaster Fairy, Possum, 2 Leopard Wrasses, Kole, & Atlantic Blue Tangs, 2 Percula Clown, 3 PJ and 1 Banggai Cardinalfish , Swallowtail, Bellus and Coral Beauty Angels |

|

|

|

|

|

#24 |

|

Registered Member

Join Date: May 2006

Posts: 2,354

|

That's a great idea Floyd I've never seen that type of build before. Pretty nifty.

|

|

|

|

|

|

#25 |

|

Either busy or sleeping

|

To be fair though, I've never built one. So it looks good on paper, just have to make sure that it works correctly for your tank.

I like hgkar's build too. Works if you have a lot of flow.

__________________

Algae Scrubber Basics!!! GOOGLE "algaescrubber zoho" General Interest Forums --> Advanced Topics --> Algae Scrubber Basics (sticky) --> POSTS #3251-64 (Basics), #5206 (Cleaning), #6884 (LEDs), #729 |

|

|

|

|

| Tags |

| algae scrubber, ats, diy, plumbing, turf scrubber |

|

|